Thank you for visiting the Miyoshi Oil & Fat co.,LTD booth of Asia Water 2024!

This page provides examples of use of the exhibited products.

You can send inquiries for products and sample request.

<introduction of exhibited products>

・EPOFLOC(Heavy metal scavenger)

・Case Study

ーIssues : When it contains various heavy metals

ーWhat can EPOFLOC do?

・Features

・Treatment testing method

ーTesting method

ーTesting is performed to determine the amount of Epofloc to be added

ーPoint

【EPOFLOC(Heavy metal scavenger)】

EPOFLOC is a liquid type chelating agent that is made in Japan.

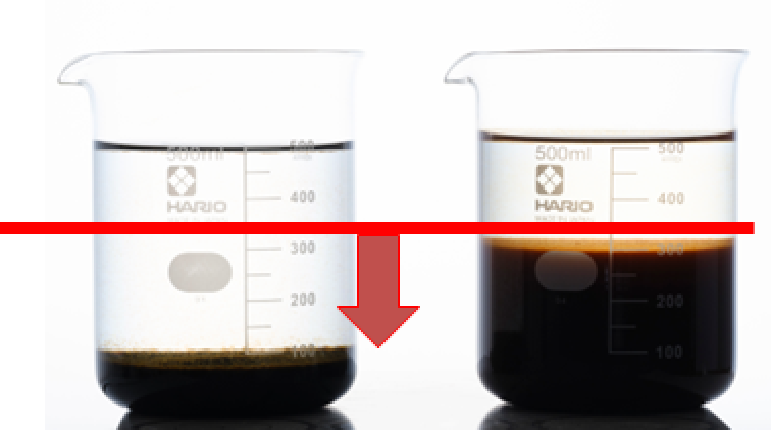

It has extremely high reactivity as it directly chelate bond with heavy metal ions in wastewater and forms large floc which creates immediate precipitate.

Wide range of heavy metals can be treated efficiently with low dosage.

【Case Study】

◆Issues : When it contains various heavy metals

Are you having trouble dealing with wastewater that contains multiple heavy metals?

In factories that handle various metals, such as the metalworking and plating industries, various metal ions are dissolved in wastewater.

When multiple metals are contained in wastewater, it is actually difficult to remove all metals from the wastewater and keep them below the standard value.

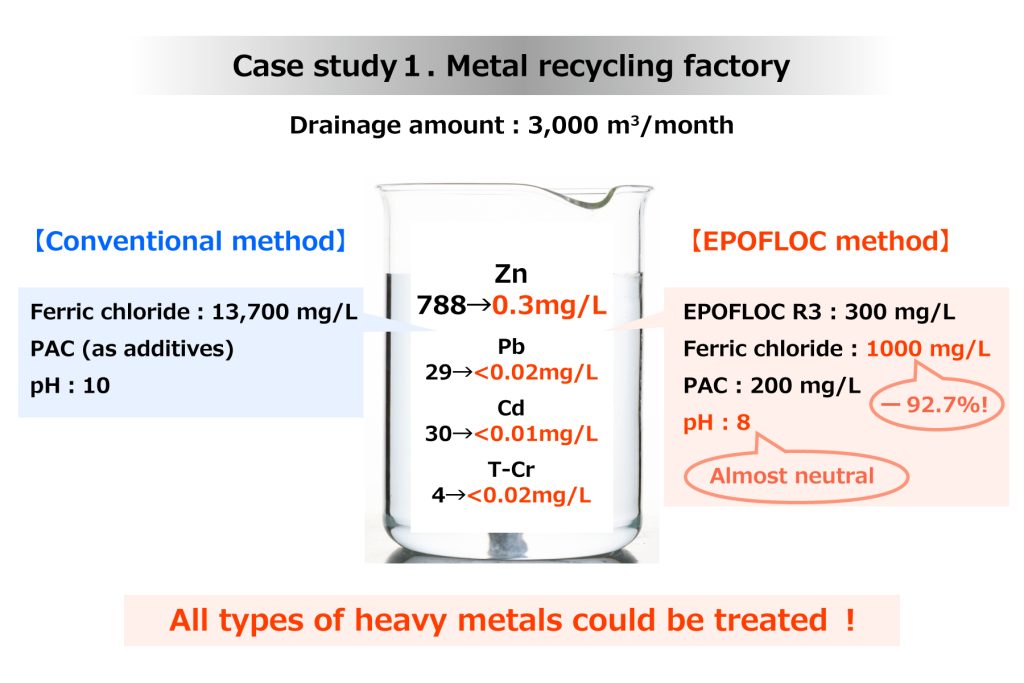

Case study 1.Metal recycling factory

●Drainage amount:3,000 m3/month

◆What can EPOFLOC do?

By using EPOFLOC R3, even wastewater containing various heavy metals can be treated below the standard value!

👍Good Point!

While reducing the amount of chemicals, all types of heavy metals could be treated below the regulation value.

👍Good Point!

Processing was possible under almost neutral conditions without raising the pH too much.

【Features】

Efficient with low dosage

As EPOFLOC directly reacts with heavy metal ions and creates strong chelate bond, it can flocculate

and precipitate heavy metal ions even with low dosage.

EPOFLOC reacts well with heavy metal ions even if

the wastewater is high concentrated complex wastewater, which saves the dosage to be used.

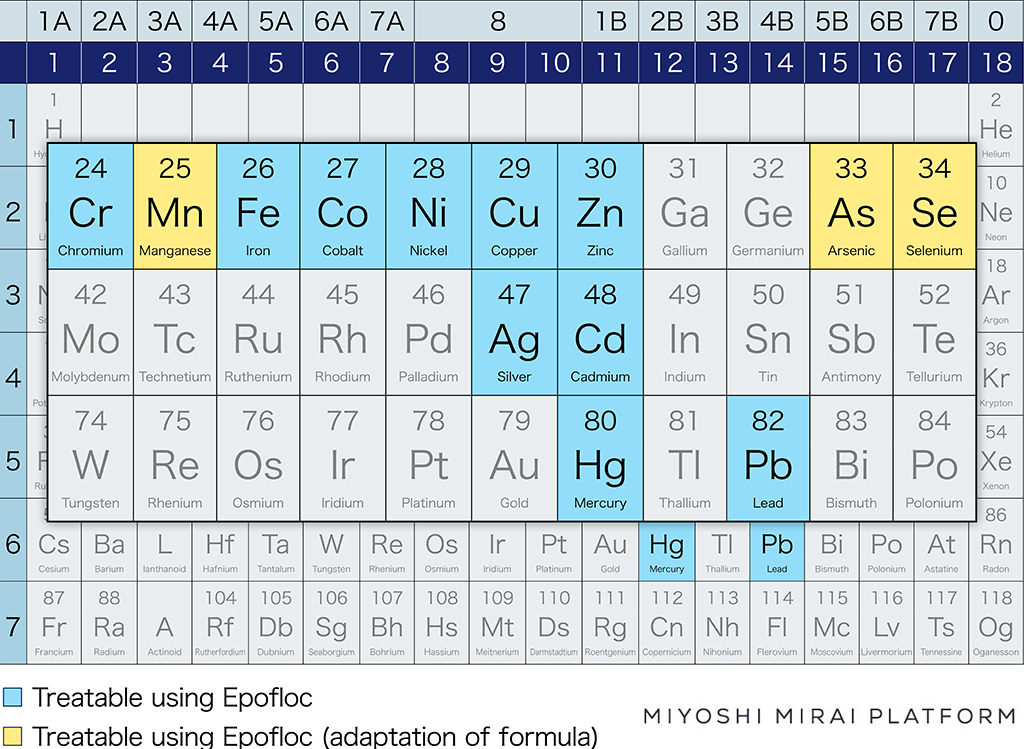

Wide variety of heavy metals can be treated

EPOFLOC reacts with variety of heavy metals such

as Chromium (Cr), Manganese(Mn), Iron (Fe), Cobalt (Co), Nichel (Ni), Copper (Cu), Zinc (Zn), Arsenic (As), Selenium (Se), Silver (Ag), Cadmium (Cd), Mercury (Hg), Lead (Pb) and etc.

Significant sludge reduction

Compared to the conventional chemicals, EPOFLOC can reduce the amount of both agents

and additives to be used which results in significant sludge reduction.

You can see a video of the wastewater treatment flow using “EPOFLOC” on a beaker scale and the difference from the conventional method.

【Treatment testing method based on the use of EPOFLOC】

When the use of EPOFLOC in a heavy-metal treatment plan is investigated, treatment testing should be conducted using actual wastewater. As long as you have a beaker, an agitator, and a stirring bar, you can perform treatment testing on your own and easily check the effectiveness of EPOFLOC.

The basic steps for treatment are as outlined in steps (1) through (6) below.

The conditions, such as the type of auxiliary agent and amount to be added, are set based on the facility in question.

◆Testing method

(1) Setting of the amount of EPOFLOC to be added

(2) Addition of EPOFLOC

(3) Addition of an auxiliary agent

(4) The pH adjustment

(5) Addition of a polymer coagulant flocculant

(6) Standing of the mixture

◆Testing is performed to determine the amount of EPOFLOC to be added.

◆Points

◆Testing method

(1) Setting of the amount of EPOFLOC to be added

The amount of EPOFLOC to be added is set.

*Care should be exercised because an incorrect amount could render the addition of EPOFLOC ineffective.

(2) Addition of EPOFLOC

The mixture is agitated rapidly (for approximately 10 to 20 min).

Large flocs are generated in approximately 5 to 10 min.

(3) Addition of an auxiliary agent

An auxiliary agent is added, and the mixture is agitated rapidly (for approximately 10 to 20 min).

*The ratio of EPOFLOC to the auxiliary agent is normally between 1:3 and 1:10.

*Auxiliary agent: Examples include a ferric chloride solution, poly-iron, aluminum sulfate, and PAC.

(4) The pH adjustment

The pH is adjusted to the treatment level (between 5 and 9).

(5) Addition of a polymer coagulant flocculant

A polymer flocculant is added. The mixture is agitated slowly (for approximately 1–5 min) before allowing to stand.

(6) Standing of the mixture

The mixture is agitated slowly and allowed to stand before the treated water is separated from the sludge that accumulates at the bottom of the beaker.

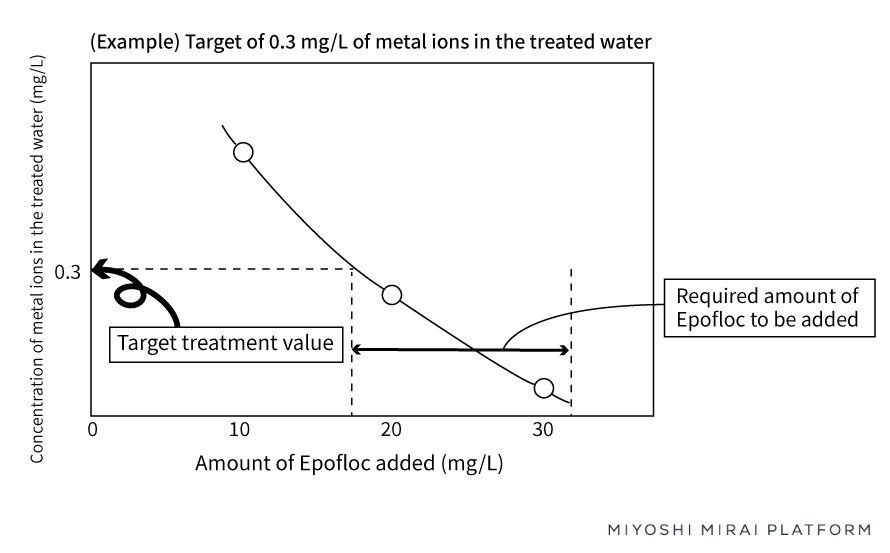

◆Testing is performed to determine the amount of EPOFLOC to be added.

Actual wastewater is used to determine the optimal amount of EPOFLOC to be added.

1. The amount of EPOFLOC to be added (such as 10, 20, or 30 mg/L) is set.

2. A beaker test is conducted according to the testing method described above.

3. The concentration of heavy-metal ions in the supernatant resulting from step (6) of the treatment process (letting it stand) (or after filtration) is measured.

4. The relationship between the amount of EPOFLOC added and the concentration of heavy-metal ions is graphed.

5. The amount added, which should be no more than the target treatment value, is the required amount to be added

(When the target treatment value is not reached, the amount of EPOFLOC added is increased.)

◆Points

- The amount of EPOFLOC added varies according to the concentration of heavy-metal ions in the wastewater.

- Although a ferric chloride solution was used as the auxiliary agent in this test, you can also use poly-iron, aluminum sulfate, or PAC. In addition, you should consider progressively adding 3–10 times the amount of EPOFLOC that is added, such as adding 30, 50, or 200 mg/L of EPOFLOC.

- Although the optimal treatment pH level for EPOFLOC is 7 or 8, it is possible that a better outcome can be achieved with a pH level of 5, which is in the acidic range, or a pH level of 9 or 10, which is in the alkaline range. The level should be investigated accordingly.

- Where the pH level of raw water is less than 4, the pH level should be adjusted to raise it to 4 or higher before adding EPOFLOC.

If you have difficulties determining the amount of EPOFLOC to be added or the method of treatment to be implemented, feel free to inquire with us.

In addition, we provide one-stop solutions to the needs of our clients by offering — among other options — EPOROUS, a chelating resin for wastewater treatment that selectively absorbs heavy metals, and EPORVA, a liquid chelating agent for the treatment of fly ash that works by immobilizing harmful heavy metals contained in fly ash generated at garbage incineration plants and other waste incineration facilities.